Explore All Products

Make An Enquiry By Filling The Form!

Diesel Electric Locomotive Aftermarket Parts- EMD

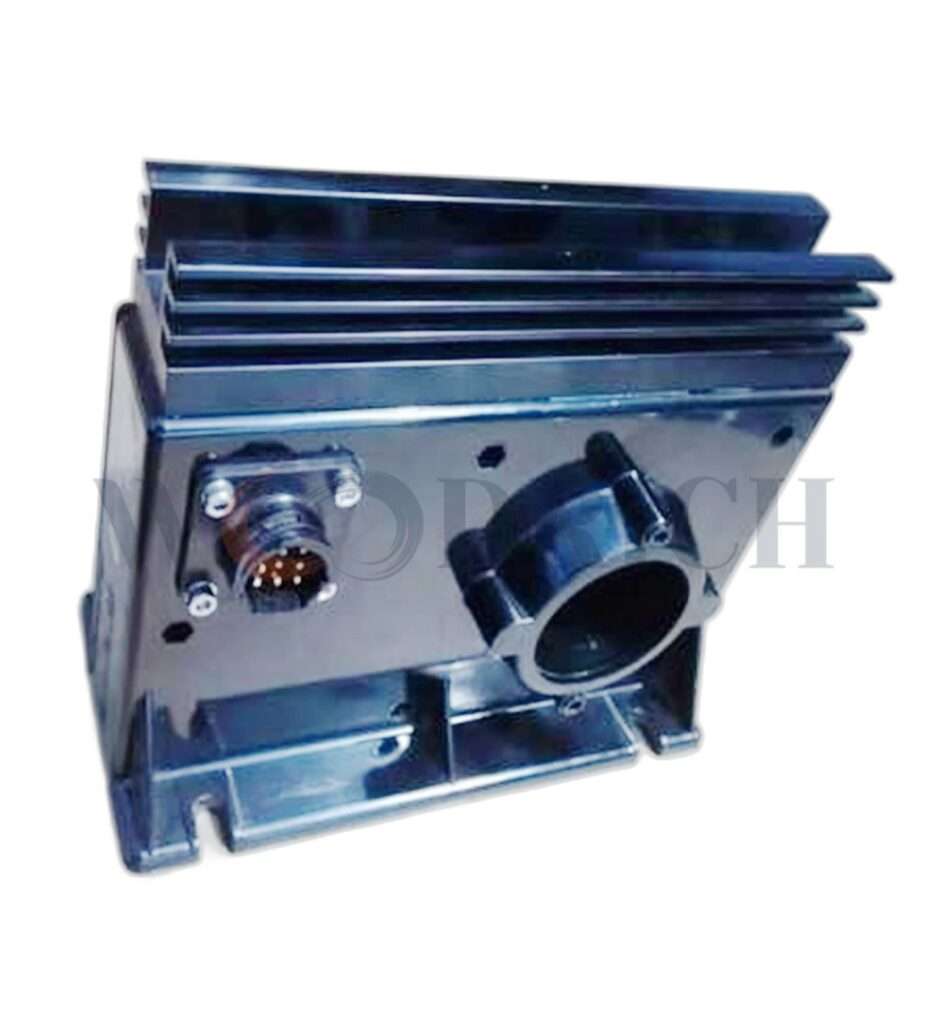

FUEL PUMP MOTOR

OEM PART NO. 40122943

This motor is available with these part Nos. 17454633, 40077367, 40302210, GE132x1820

Description:

The diesel locomotive’s heart is the fuel pump. Fuel that is given precisely preserves a timing or rhythm that keeps the engine operating efficiently. The pump simultaneously regulates the quantity of fuel required to provide the required power.

These goods, which come in various ratings, are what we manufacture for locomotive applications. This product has been validated by numerous railway manufacturers worldwide and is certified in accordance with IEC requirements.

Specifications:

- Power Capacity: Continuous 800W, Peak 1500W

- Supply of Voltage: 40 Volts DC To 90 Volts DC

- Nominal Voltage: 74 VDC

- Input Current: 8A @74 VDC with 40 Psi pressure continuous Max.15A @74 VDC with 120 Psi pressure.

Applications:

All EMD engine models 567, 645, 710 and all ALCO GE Diesel models.

FUEL PUMP MOTOR: VARIANT 8GPM

OEM PART NO. 10659917

TURBO LUBE OIL SOAK BACK PUMP

OEM PART NO. 40182032

(VERTICLE TYPE –AC)

Description:

To prevent costly and needless turbocharger problems, turbo soak-back pumps are utilized for cooling and lubricating turbochargers right away after the engine is turned off. It also serves as a turbo pre-lube pump, which is essential protection for the engine during start-up.

Specifications:

- Power Capacity: Continuous 640W

- Supply of Voltage: 40 Volts DC To 90 Volts DC

- Nominal Voltage: 74 VDC

- Input Current: A @74 VDC with 40 Psi pressure continuous Max. 12A @74 VDC with 120 Psi pressure

Applications:

All EMD engine models 567, 645, 710 and all ALCO, GE, Diesel models. Inverters are circuits that convert DC to AC i.e. transfers power from DC source to AC load at the required frequency and amplitude.

INVERTER FOR FUEL PUMP MOTOR

OEM PART NO. 40122943, 11815565, 40922143

Description:

This is the child part of Fuel Pump Motor of EMD locomotives that converts the DC to AC with required power with respect pump capacity. Its a direct replacement with similar model of fuel pump in any locomotives.

Specifications:

- Output Waveform: Quasi-Sine wave

- Power Capacity: Continuous 800W

- Peak: 1500W

- Supply of voltage: 40 volts DC TO 90 VOLTS DC

- Nominal Voltage: 74 VDC

- Input Current: 8 A @ 74 VDC with 40 Psi pressure continuous

- Max. 15A @ 74 VDC with 120 Psi pressure

- Output Frequency: 50-60 Hz

Applications:

For all Kinds of Diesel Locomotives fitted with vertical type Fuel Pump Motor.

LOCOMOTIVE SPEED SENSOR

OEM PART NO. 40081692

Description:

The Locomotive Speed Sensor measures the absolute ground speed that can be reliably used as the reference vehicle speed. By comparing the Doppler speed with each rotating axle speed, the slip/slide can be found for each axle, this method is issued on the GT46MAC or PAC (WDG4/WDP4locomotives).

Specifications:

- 15VDC (+/-0.25)

- 0.5Amps

- 24.160GHz

- Ground speed: 22.2 Hz/mph

- Integral Antenna.

Applications:

For all EMD Super Series Locomotive models.

CONTACTOR: GENERATOR FIELD CURRENT (GFC)

OEM PART NO. 8330937

Description:

Connecting the exciter generator supply to the main generator field for field excitation is the function of the GFC contactor. When circuits are finished for power operation, dynamic braking, or load testing, the contactor detects it. The EM2000 controls the GFC contactor, which senses when circuits are finished for load testing, dynamic braking, or power operation.

Specifications:

- Working voltage: 74vdc

- Max pickup: 48vdc

- Dropout: 5-28vdc

- Contacts: 2NO 100Amps 230V AC

- Aux Interlocks: 2 NO –NC 10Amps

Applications:

For all EMD Super Series Locomotive models.

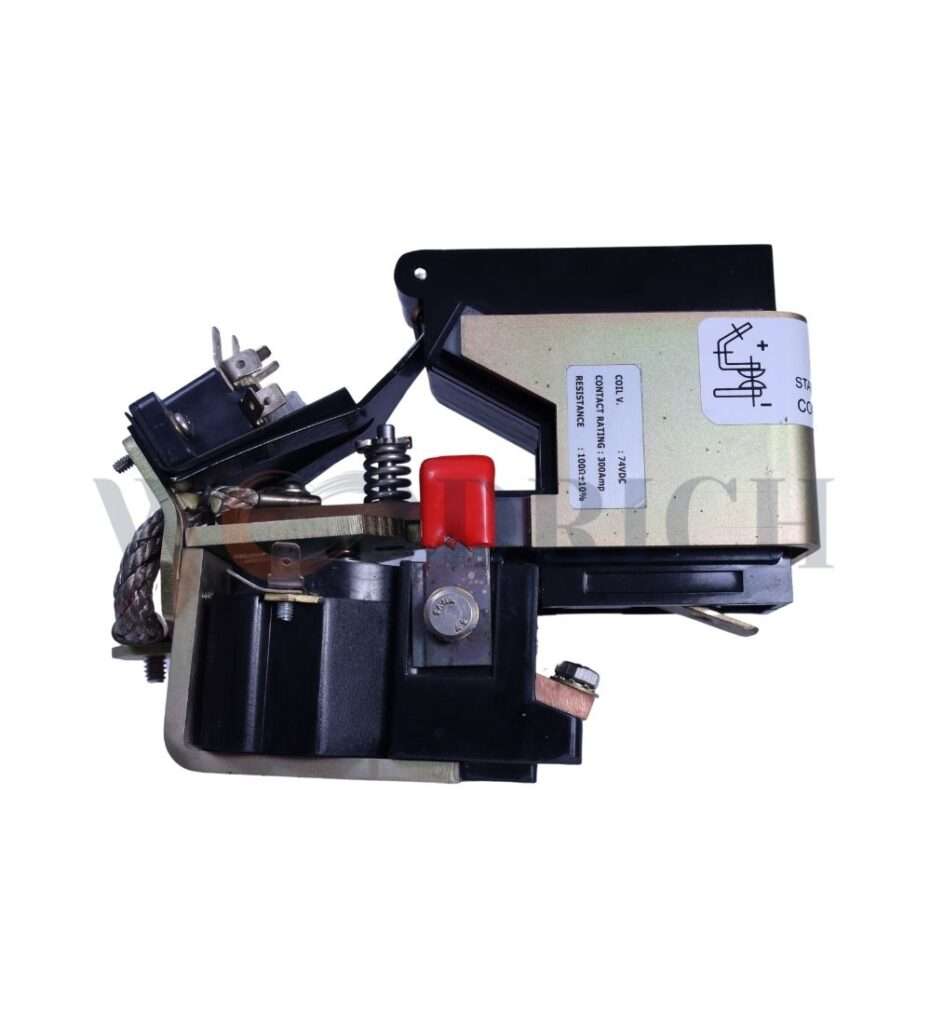

CONTACTOR: STARTING-DC (ST)

OEM PART NO. 9325207

Description:

It is an electromagnetic device that is used to create and break circuits in a variety of high-current electrical circuits. The movable tips of this contactor move on the fixed tip when the coils are energized, magnetizing the core. The coil’s core demagnetizes when the current is removed, and spring action causes the movable contacts to open from the fixed contact. The EM2000 receives the same data that ASSY uses to act on No-NC logic to control the circuit.

Specifications:

- Contact Rating: 2000Amps

- Working voltage: 74vdc

- Main contacts: 2 NO-NC

- Pickup voltage: 34 Volts

- Drop voltage: 3-16V

Applications:

For all EMD Super Series Locomotive models.

CONTACTOR: STARTING AUXILLARY (STA)

OEM PART NO. 8482180

Description:

The working principle is as above but in the locomotive, the First to be picked up is the STA contactor. Energizing the DIO output channel accomplishes this. Since the ST contactor is picked up via the STA interlocks, this contact needs to be picked up first. The DIO module does not directly activate the STA.

Specifications:

- Continuous rated current: 2 pole 30 Amps,

- Aux Interlocks: 3NO,1NC-10Amps

- Coil magnet: 66.6 ohms.

Applications:

For all EMD Super Series Locomotive models.

CONTACTOR: GENERATOR FIELD DECAY (GFD)

OEM PART NO. 40010561

Description:

In high-voltage circuit breakers and switchgear, a field decay (GFD) contactor—also referred to as a suppression contactor—is a component used to control voltage spikes during current interruption. Severe voltage spikes can result from the collapsing magnetic field caused by the disconnecting of an inductive load, such as a motor or transformer. This field can decline gradually instead of abruptly thanks to the GFD contactor.

Specifications:

- Continuous coil rating: 74V

- Coil resistance: 100OHMS,

- Pickup: 48 VDC

- Dropout: 5- 25 VDC

Applications:

For all EMD Super Series Locomotive models.

GR RELAY

ALL PART NO. 40050359/ 8360045/ 8383122/ 8361776

Description:

One crucial safety relay used in electric locomotives is the ground relay (GR). Here are some essential details regarding how it operates: It finds ground problems in the traction motors and circuits of locomotives. This guards against harm to the equipment. It tracks the current that travels from the locomotive’s wheels to the earth. Normally, this is quite close to zero. Current will return to the locomotive body through the soil in the event of a ground fault. When GR notices this, the circuit breakers trip.

Specifications:

- Operating Voltage: 74vdc

- Pickup Voltage: 48vdc max

- Pickup current: 0.750 to 0.825 amp

- Contacts: 4 N.O & 2 N.C

- Coil Resistance: 0.86 Ω

Applications:

All types of EMD locomotive models controlling system cabinets.

GENERAL PURPOSE RELAY 2 POLE

OEM PART NO. 40050359

Description:

When the FUEL PRIME/ENGINE START switch is placed in the engine start position and DIO 1 output channel 18 is turned “ON” by EM2000 (if software conditions are fulfilled), STA main contact closes to apply battery power to the “pick up” solenoids that are part of the starting motors assembly.

Specifications:

- Contact Rating: 10Amp 74VDC

- Coil Rating: 1853Ohms +/-15

- Pickup: @48VDC

- Drop out: @5-32 VDC.

Applications:

All types of EMD locomotive models controlling system cabinets.

GENERAL PURPOSE RELAY 3 POLE

OEM PART NO. 8357415

Description:

Often referred to as a multi-purpose relay, a general-purpose relay is a straightforward electromechanical relay intended for a broad range of switching and control applications. A magnetic field produced by the activated coil pulls the armature and shifts the contacts’ positions. There are three types of contacts: changeover, typically closed, and normally open. Permit several circuits to be controlled.

Inexpensive, simple to use, swap out, and maintain. incredibly adjustable with a wide range of choices. Proven and reliable technology.

Specifications:

- Contact Rating: 10Amp 74VDC

- Coil Rating: 1128Ohms +/-15

- Pickup: @48VDC

- Drop out: @5-32 VDC

Applications:

This is for all EMD Super Series Locomotive Models.

GENERAL PURPOSE RELAY 4 POLE

OEM PART NO. 9516672

Description:

Often referred to as a multi-purpose relay, a general-purpose relay is a straightforward electromechanical relay intended for a broad range of switching and control applications. A magnetic field produced by the activated coil pulls the armature and shifts the contacts’ positions. There are three types of contacts: changeover, typically closed, and normally open. Permit several circuits to be controlled.

Inexpensive, simple to use, swap out, and maintain. incredibly adjustable with a wide range of choices. Proven and reliable technology.

Specifications:

- Contact Rating: 10Amp 74VDC

- Coil Rating: 1128Ohms +/-15

- Pickup: @48VDC

- Drop Out: @5-32 VDC

Applications:

This is for all EMD Super Series Locomotive Models.

ENGINE PROTECTION DEVICE

OEM PART NO. 9320130

Description:

The Engine Protection Device (EPD) protects the engine against all abnormal conditions that can be harmful to the engine such as overspeed, low oil pressure, low coolant pressure, low/high coolant temperature, high crankcase pressure, hot lubricating oil, and overload. If the device detects the positive crankcase pressure or low coolant level, the appropriate detector senses this condition and initiates engine shutdown.

Specifications:

- Operating Pressure: 100psi water level,

- Crank Case: Device to trip at a pressure of 0.8 inches of WC to 1.8 inches of WC.

Applications:

For all types of EMD engine model 567, 645, 710 with different cycles.

DETECTOR ASSEMBLY KIT/ EPD KIT

OEM PART NO. 9535869

Description:

The worn-out component elements of the primary detector assembly are to be replaced with the Engine Protection Device Kit (Kit Detector). These are the child parts that need to be changed when the main assembly needs to be renovated. hence the installed assembly on the locomotive ought to run faultlessly.

Specifications:

- Operating pressure- 100psi water level

- Crankcase- device to trip at a pressure of 0.8 inches of WC to 1.8 inches of WC

Applications:

For all types of EMD engine model 567, 645, 710 with different cycles.

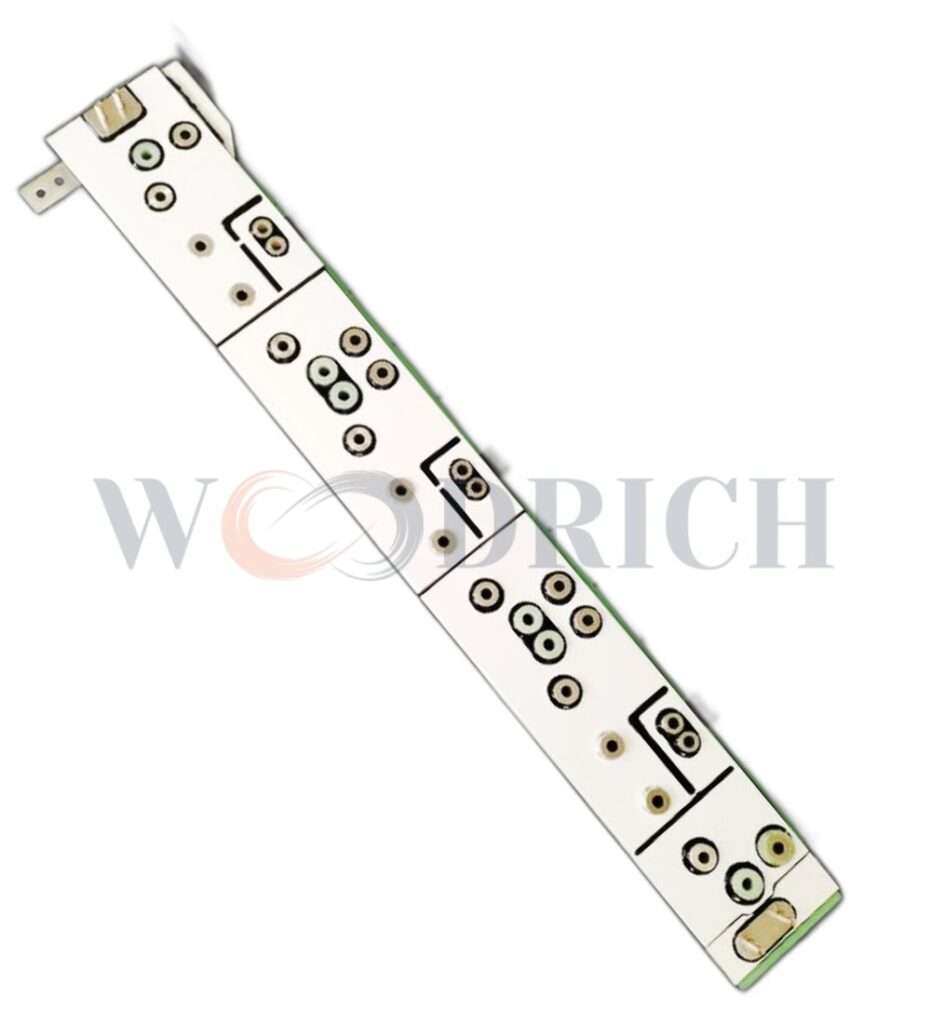

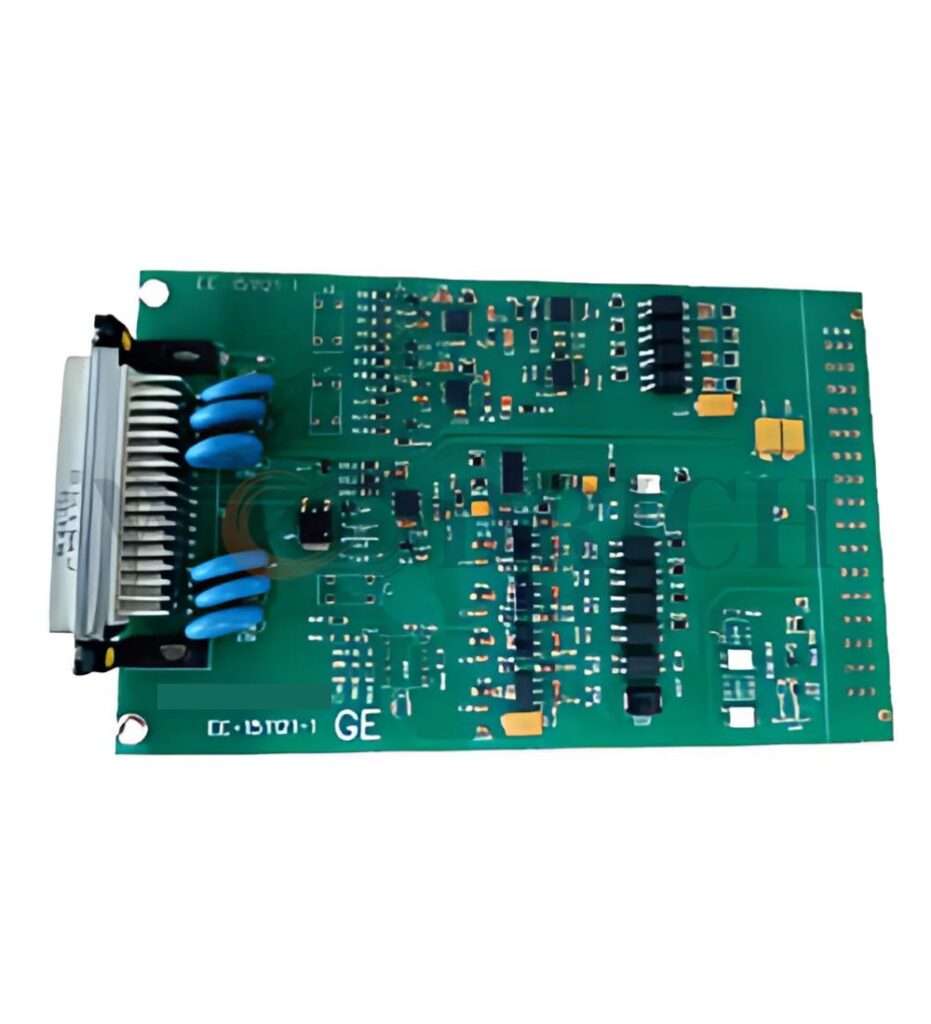

PANELMODULE ASC 300 (ANALOG SIGNAL CONDITIONER MODULE)

OEM PART NO. 40042056 Alt Ca

Description:

The ASC serves to condition analog feedback into DC voltage signals that can be handled by the ADA. It also provides +5 VDC power to the Barometer. This module converts analog signal to digital signal.

Specifications:

- Input voltage: +15, -15Vdc to the Isolation amplifier, required for the ADA Card.

Applications:

For all Sd Super Series EMD Diesel Electric Locomotive replacements, the locomotive holds with EM-2000 control system.

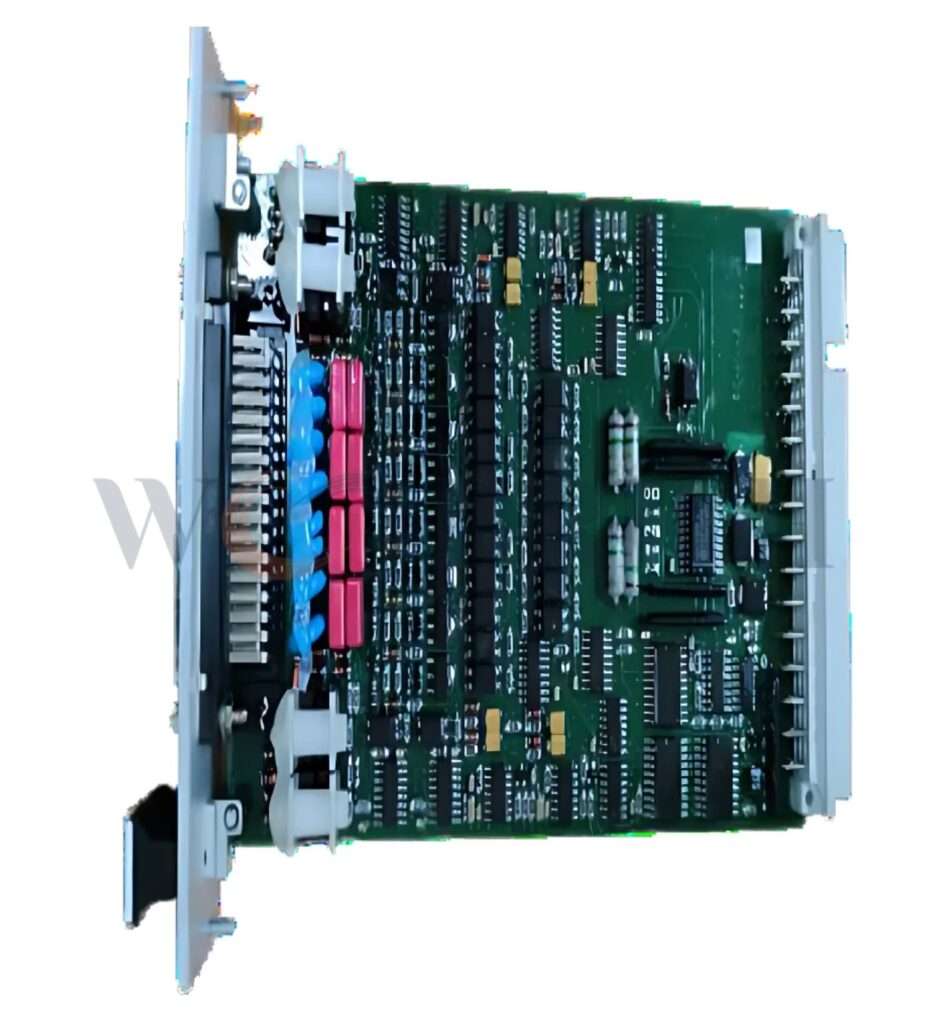

CIRCUIT MODULE PRG 301

OEM PART NO. 0081644 ALT Ba

Description:

The PRG301 is the power conditioner used in PSM modules. It receives its input from the Aux Gen/Battery circuits. The PRG operates as a low pass filter with the output being somewhat below the input by around 1 VDC when the active boost circuitry is switched off. The PRG further serves as a power-dissipating resistor when the input is too high. About 80 volts is when the resistive circuitry activates.

Specifications:

- Input Voltage : 25-68V DC

- Output Voltage : 64-77V DC

- Resistive Circuitry : 80V DC

- Voltage At The Load : 4.75V DC & 5.25V DC

- Frequency : 50 HZ

Applications:

For all SD super series EMD diesel Electric Locomotive replacements, the Locomotive holds an EM-2000 control system.

CIRCUIT MODULE TLF (Trainline Filter Module)

Description:

Train line filter input voltage 74V and output voltage min 9V to 12Vdc.

CIRCUIT MODULE - DIO-300

OEM PART NO. 40030373

Description:

The CIRCUIT MODULE-DIO 300 is probably a replaceable circuit board for digital interfaces that can handle a variety of analog and digital input/output signals. Its purpose is to work with a certain line of rail equipment products. In order to monitor status metrics and regulate electromechanical components, it would interact with a variety of sensors and control systems within an EMD diesel locomotive. It can be connected to a variety of signals, such as pressure transducers, relay actuators, temperature probes, voltage sensors, current sensors, and switch sensors. The circuit board would handle an analog voltage in addition to digital signals that were either one or zero logic.

Applications:

For all SD (super series EMD diesel Electric Locomotive replacements, the Locomotive holds an EM-2000 control system.

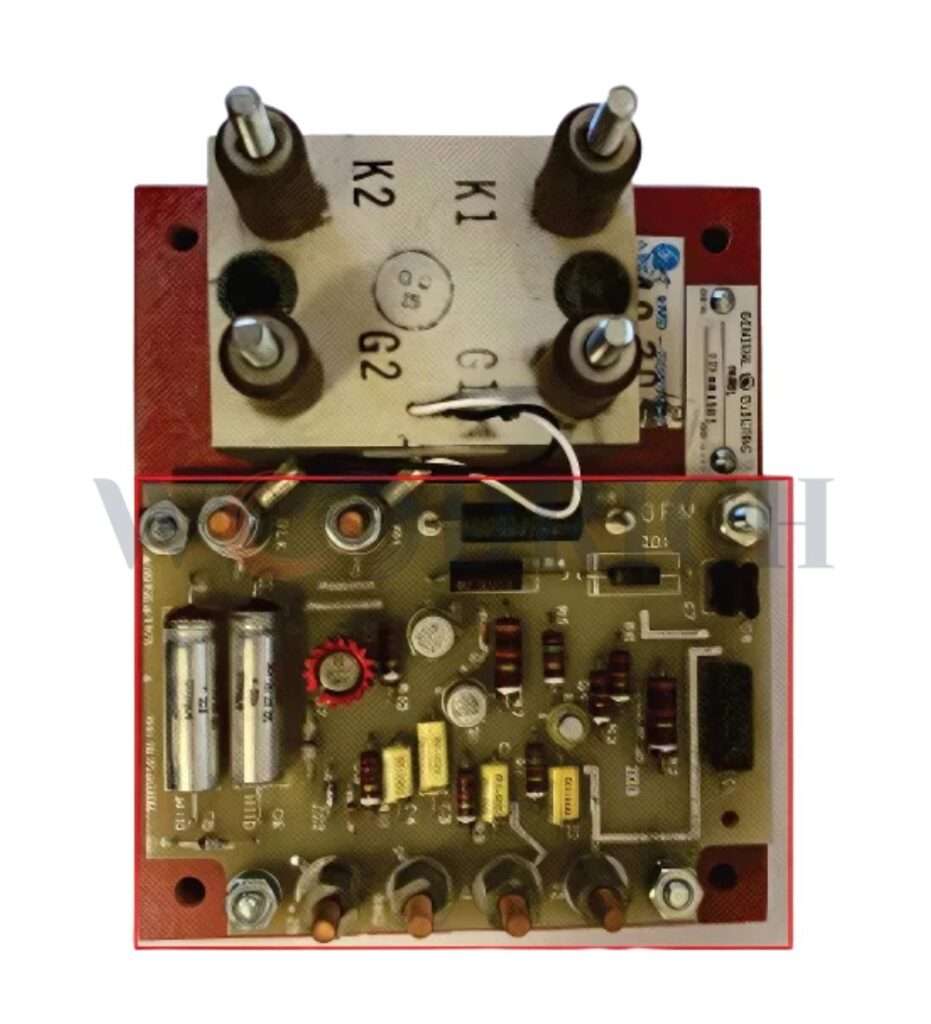

SCR ( Silicon Controlled Rectifier) Exciter Bridge Assembly

OEM PART NO. 8451653

Description:

The exciter bridge converts DC power from the locomotive’s auxiliary system into AC power to energize the main generator’s field windings. This controls the output voltage of the main traction generator that powers the electric traction motors. The exciter bridge receives DC voltage from the locomotive’s auxiliary electrical system. Based on gate signals from the excitation controller, the SCRs rectify this into controllable three-phase AC power to excite the main generator’s field.

Specifications:

- Nominal 240 volts RMS

- Maximum 265 volts RMS

- Frequency 35 to 126.

Applications:

For all EMD Diesel Electric Locomotives.

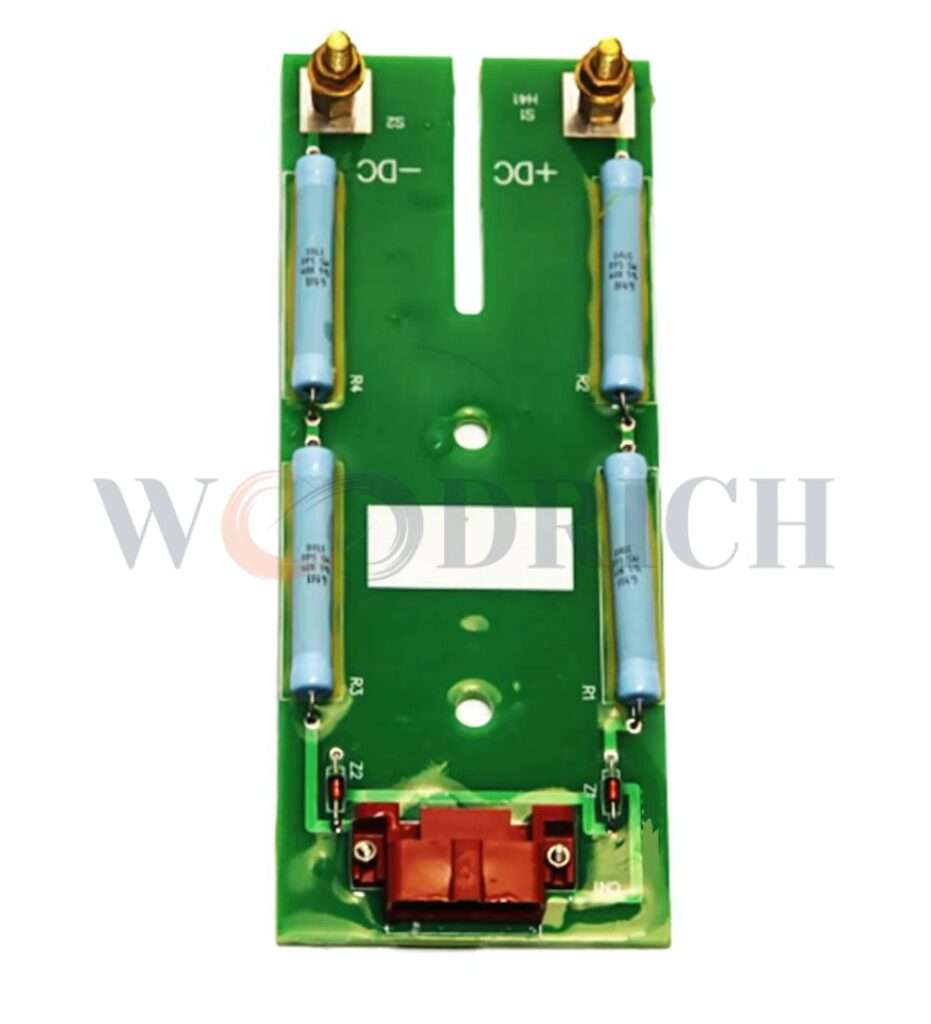

Rectifier & Resistor Assembly Battery Charger (BCR)

OEM PART NO. 8479400

Description:

In diesel-electric locomotives, the primary battery charging mechanism is the rectifier and resistor assembly.

Rectifier: To charge the batteries, this device transforms the main traction alternator of the locomotive’s AC electricity into DC current. usually makes use of silicon diodes in a circuit for a full-wave bridge rectifier.

Assembly of Resistors: includes resistors set up in parallel and series to regulate and restrict the DC output current used to charge the batteries, enables batteries to share current. The resistor assembly receives the rectified DC and uses it to provide the locomotive’s lead-acid batteries with a regulated charging current.

Specifications:

- Input Nominal Voltage: 55 volts RMS Max 75Volts RMS 3 Phase

- Frequency: 35 to 126Hz

- Output: 65-75 VDC 150Amp Max for battery charging resistor and rectifier 65-75 VDC

- 250 Amps Max for 3 phase Bridge.

Applications:

For all EMD Diesel Electric Locomotives.

Note:

This item is available in different parts Nos. 8475590, 8451653

STANDBY INVERTER FOR FUEL PUMP MOTOR

OEM PART NO. 40122943/ 11815565 / 40922145

Description:

A standby inverter acts as an emergency backup source system that temporarily powers essential loads when the mains inverter fails on the locomotives. It’s a key appliance for minimizing disruption and line detention because of fuel pump failure.

Specifications:

- Output Waveform: Quasi-Sine wave

- Power Capacity: Continuous 800W Peak 1500W

- Supply of voltage: 40 volts DC TO 90 VOLTS DC

- Nominal Voltage: 74 VDC

- Input Current: 8 A @ 74 VDC with 40 Psi pressure continuous

- Max.15A @ 74 VDC with 120 Psi pressure

- Output Frequency: 50-60 Hz

Applications:

For all Kinds of Diesel Locomotives fitted with vertical-type fuel Pump motors.

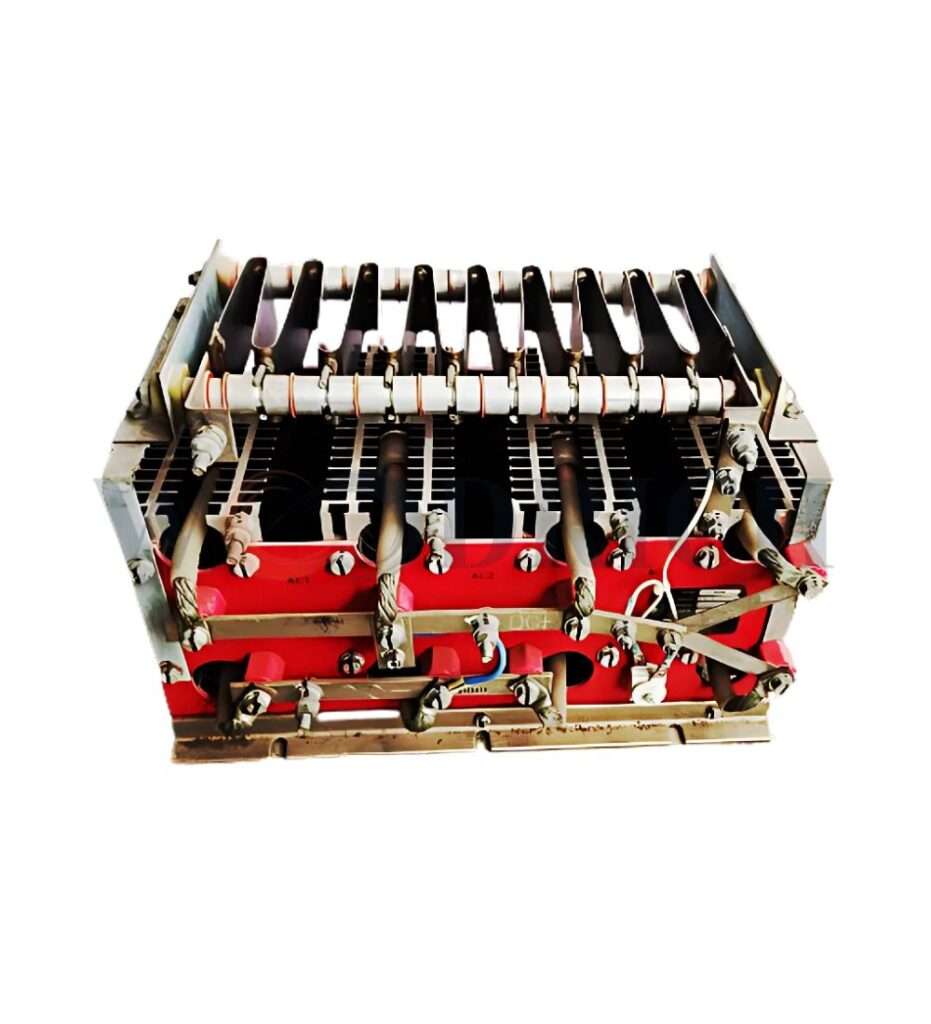

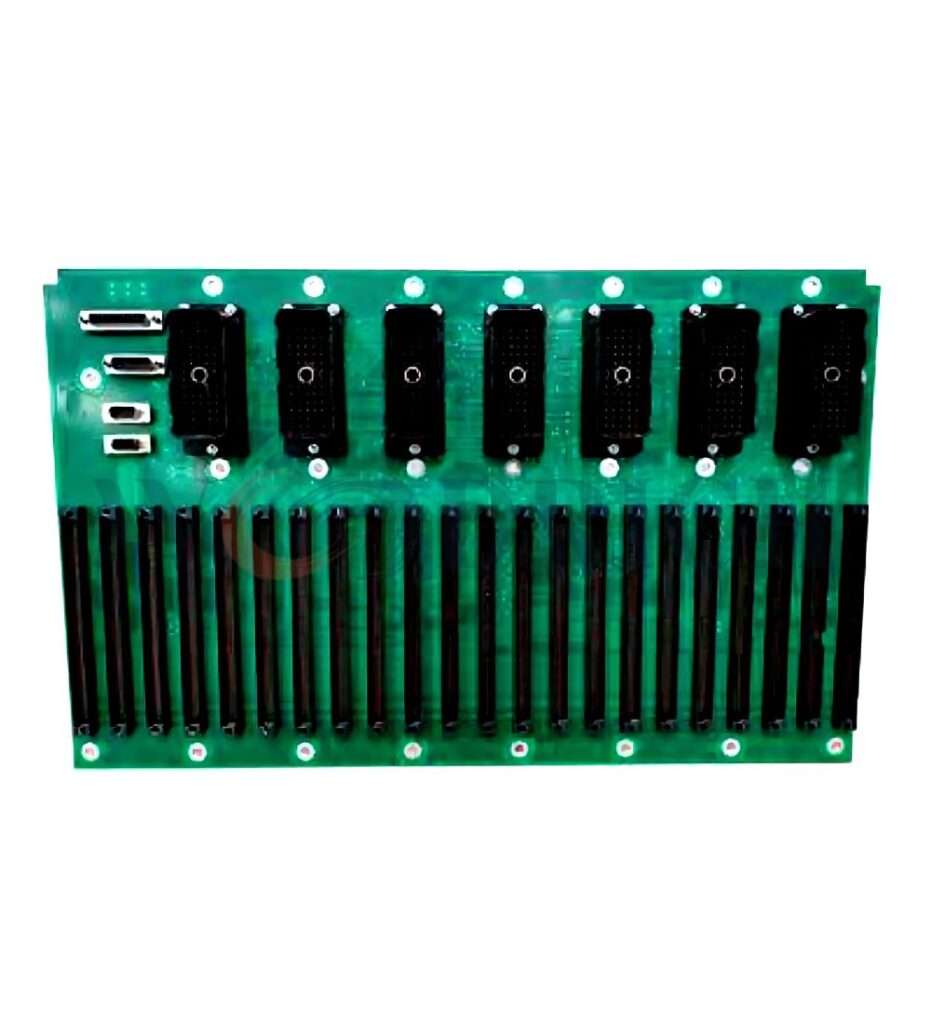

RECTIFIER BANK ASSEMBLY

OEM PART NO. 40027895 ALT CA

Description:

An alternator or generator that uses alternating current (AC) to generate direct current (DC) is equipped with a rectifier bank assembly.

Specifications:

- Input Nominal: 240 volts RMS

- Maximum: 265 volts RMS

- Frequency: 35

- Diode Specification: If diode is forward bias: 10 to 20Ω

- If diode is reverse bias: 30,000Ω

- Resistance: 2500Ω

- Fuse Current Limiting: 350Amps

- Body of Fuse is Made of reinforced melamine

Applications:

This is for AR10, AR12 and TA17, TA-20 for all kind of Diesel Locomotive Alternator.

WATERPUMP REPAIR KIT

OEM PART NO. 40000927

Description:

Rather of having to replace entire pump assemblies or individual components, locomotive water pump repair kits save time and money by containing all the necessary parts in one package. In order to guarantee optimal pump life and performance, precise rebuilding techniques are essential. For diesel locomotive engines, a water pump repair kit usually includes all the parts needed to rebuild or overhaul the water pump without having to replace the complete pump assembly.

Specifications:

- As per the Kit EMD part numbers mentioned and by Specific Components Drawings.

Applications:

For all EMD 567, 645, 710 Engines LH and RH pumps of the engine.

SLIP RING ASSEMBLY

OEM PART NO. 8345866

Description:

Alternating current generation and the transfer of high current from the spinning rotor’s windings are made possible by the slip ring assembly. It is an essential part of the alternator. Its function is to allow the rotor to revolve inside the stator while conducting current to the rotor windings. This facilitates the transfer of the power produced by the rotor’s rotation. It is made up of carbon or graphite brushes that make contact with a series of slip rings that are installed on the rotor shaft. The rotor windings are connected to the rings.

Specifications:

- Current: 120A of continuous with peak up to 180A

- Voltage: 60VDC

- Rotating speed: 954rpm over speed up to 1080 rpm

- Conductivity: 9.6%min

Applications:

AR-10, AR-12, TA-17 for All EMD and GE Locomotives Alternator.

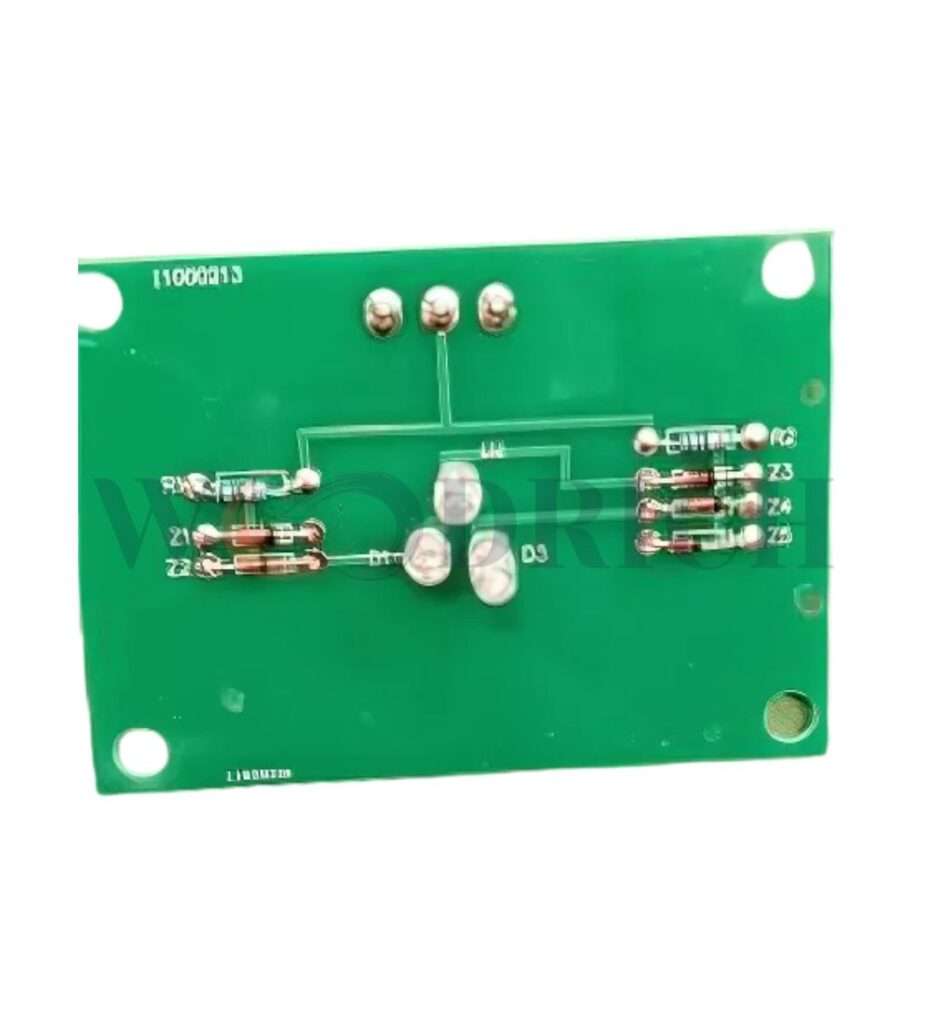

RECTIFIER ASSEMBLY

OEM PART NO.40079512

Description:

It is used in Electrical Control Cabinet. Used in the Ground Relay Transductor (GRT) circuit to prevent AC voltage from the Main Generator from being applied to the negative & positive DC generator bus output.

Specifications:

- Each capacitor: 2200PFD,1600VDC,+/_10% Philips components

- Each resistor: 10.0MEGOHMS

- Each Diode: Max Average forward current 3.0A.

Applications:

For super series EMD locomotives electrical control cabinets.

TRANSDUCTOR REACTOR

OEM PART NO.9519568

Description:

Transductor contains several control windings which act on a single output winding. The control windings are connected in circuits which sense faults that are potentially dangerous to the main generator. It is used to shunt voltage spikes that occur across T2.

Specifications:

- Power Supply: 120V, 60hz

- Rated Current: 2Amps Output

- DC Control: 2Amps Each Winding

- Maximum Burden: 1:1 Each Winding

- Rated Burden: 60 Volts.

Applications:

For all EMD Super series Locomotives models electrical control cabinets.

CURRENT TRANSDUCER 1000A (CURRENT SENSOR)

OEM PART NO.40046385

Description:

These devices have closed-loop (compensated) current sensors based on the Hall Effect. They can be applied to the measurement of pulsed, DC, or AC currents. Galvanic isolation is used by these devices to separate the low-power (electric secondary) and high-power (primary) circuits.

Specifications:

- Current rating: 1000Amps

- Ratio: 1:4000

- Power supply: +/-15VDC

- Internal resistance: 28Ohms

Applications:

For all EMD Super series Locomotives models Electrical control cabinets.

ROTATING RING RECTIFIER

OEM PART NO. 2803017

Description:

Diesel Electric locomotives often employ a revolving ring rectifier to convert the primary traction generator’s alternating current (AC) into direct current (DC) for the traction motors. Copper brushes make touch with the copper rings, which are fixed on a revolving shaft. The rings are divided into positive and negative semicircles and have insulation between them.

Specifications:

- Max. Avg. forward current: 16A

- Max. peak forward voltage drop: 1.2V

- Max. peak one cycle surge current: 300A

- Max. repetitive peak forward current: 80A

Applications:

It is used in the auxiliary generator of locomotives which converts Alternating Current (AC) to Direct Current (DC). It is used to provide control delay.

SENSOR CURRENT-1BKBL1-2

OEM PART NO. 40046384

Description:

These hall-effect current transducers measure grids blower motor current. A single-output current transformer mounted on power bus bar “BKBL1” at point “2” is identified by the symbol “Sensor Current-1BKBL1-2” in order to measure current, probably for protection or monitoring purposes. Device that senses current for a particular use. This uses the Hall effect technology principle to measure the locomotive bus bar or cable.

Specifications:

- Nominal Current: 200A RMS

- Measuring Range: 0-300A

- Supply Voltage: 15V

- Turn Ratio: 1:3000

- Current Measuring Range: 100mA for 300A

Applications:

For all Kinds of Locomotives and Industrial, other Heavy automotive .

TRACTION MOTOR SPEED SENSOR

OEM PART NO. 40142706

Description:

TM speed sensors are used in railway locomotive applications to measure the traction motor’s speed and control the brakes to prevent locking and wheel slippage. These motors are normally equipped with a transmitter wheel sensed by a speed sensor.

Specifications:

- U-Nominal 15VDC

- Range 9 to 32 VDC ± 10%Harmonic Content

- Current consumption: < 20mA (without current output)

- Frequency Range: From <0.2 Hz to 6KHz

- out put level high: < or equal to 0.8V at 15VDC ,10mA. :low :>or equal to Ub-1.8V at 15VDC ,10mA.

Applications:

For all AC and DC transmission motors with different types of output concerning sensor output and motor type.

TRACTION MOTOR TEMPERATURE SENSOR

OEM PART NO. 40153775

Description:

TM Temperature sensors are used in Railway Locomotive application to measure of armature of traction motor and also measures temperature by correlating resistance of RTD element under positive coefficient of temperature. RTDs in Traction motors measure the temperature inside the armature coil.

Specifications:

- For all AC a nominal resistance: 100Ω at 0° C (Pt 100)

- Measuring range: -50°C to +230 ° C

- Measuring Current: Maximum 1mA (no self-heating).

Applications:

DC transmission motors with different types of output concerning sensor output and motor type.

CURRENT TRANSFORMER

OEM PART NO. 8374003

Description:

In locomotive electrical systems, current transformers (CTs) are frequently employed to scale down and isolate large currents for protection and measurement. High currents are lowered by CTs to safer levels so that they can be used in relay and metering circuits. The current stepping ratio is derived from the CT turn ratio. For both metering and relaying, traction motor currents, generator field currents, etc., are monitored by CTs on locomotives.

Specifications:

- 11.8+/-10% D.C resistance

- Volts: 900RMS primary

- cycles: 25 to 75

- Current ratio: 500/0.5

- Max Bus 500A RMS

- Max Burden: 100 OHMS

- Accuracy: 1%.

Applications:

All kinds of Diesel Locomotives main Generators TA10 to TA17.

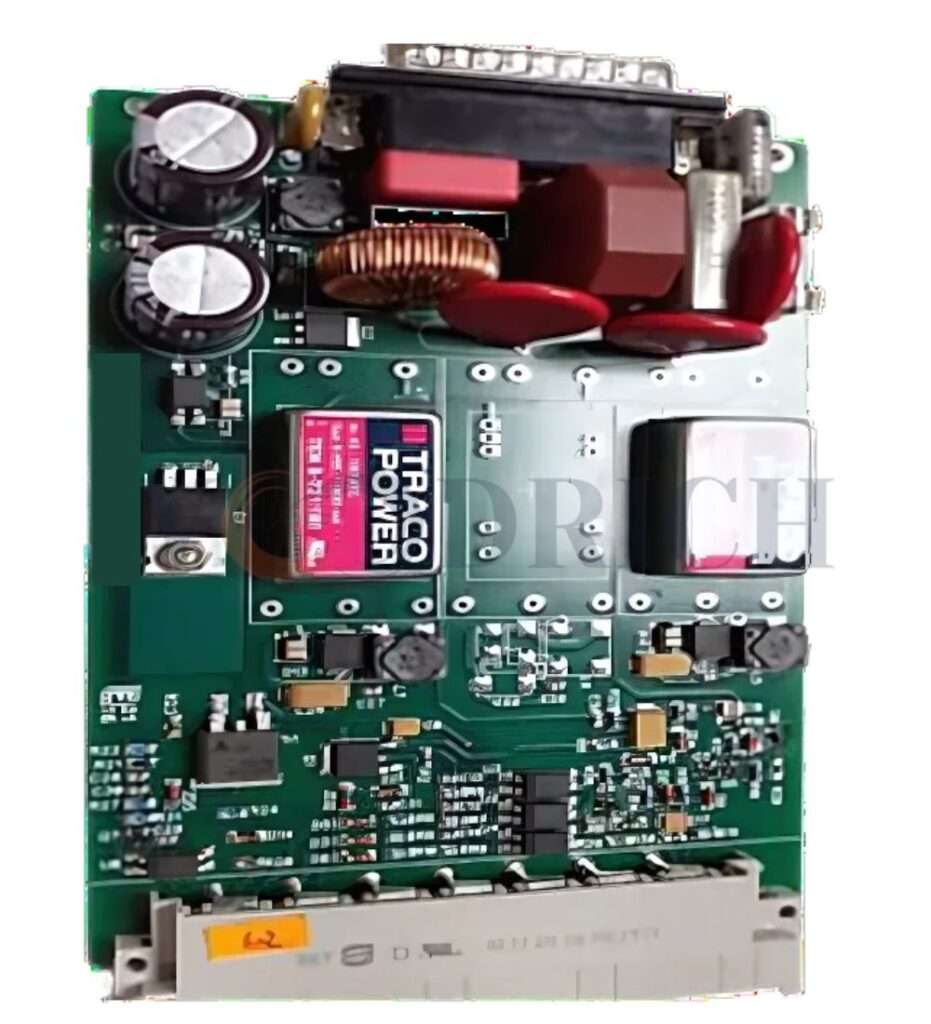

Circuit Module DVR 301

OEM PART NO. 40106746

Description:

This is a state-of-the-art computerized circuit board voltage regulator that is intended to supply steady, controlled power to the specified EMD locomotive control system. This is a Digital Voltage Regulator (DVR) circuit module which is made especially for the locomotives of the EMD SD70 series (301 model number). The DVR is a crucial electrical system module that controls the generator output voltage to keep the voltage steady enough to power all of the locomotive’s electrical components. It probably controls several generator voltage set points for various loads. It aids in power conditioning and guards against voltage dips or spikes when loads change.

Specifications:

- The voltage regulator holds the rectifier voltage at 72 V (2.22 Vdc) as a result of a change in the voltage command from 78 V to 72 V when one of the two absorption/float transition criteria is met.

- The DVR31 trips the external 15A field circuit breaker on overvoltage at 118 V rectifier voltage to prevent damage to the control circuit and equipment connected to the rectifier bus.

- The low voltage power supply provides +12 V control power to the circuit board.

Applications:

For all SD (super series EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system..

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Circuit Module PSM 300

OEM PART NO. 40042252

Description:

A smart power monitoring and optimization controller designed specifically for 300 series EMD diesel-electric locomotives is called CIRCUIT MODULE-PSM 300. For diesel-electric locomotives, PSM stands for power monitoring and management system. Most likely, the PSM 300 variation is made to work with particular EMD locomotive models that are part of the 300-series. It would be connected to the loco’s high-voltage systems, including the generator, motors, inverters, transformers, and others. The PSM module would receive analog voltage and current information from sensors. In addition to offering programmable management and regulation of the electrical systems, it would monitor power levels, efficiency, and defects. Voltage control, load balance, fault detection, and power optimization would be important operations.

Specifications:

- The PSM300 distributes power to the computer chassis by stepping down the PRG300's 74 VDC input to +5 VDC. You'll see that a negative 5 VDC supply is not needed for this arrangement. For the PSM 300 to operate as intended, the PRG300 must supply a minimum of 60 volts. On the faceplate of the PSM300, there are three LEDs. Operating within 5% of the supply's rated output voltage is indicated by the green LED at the top. This indicates a voltage of 4.75 VDC to 5.25 VDC at the load. A transient in the input line that is greater than the input range of 55–90 VDC is indicated by the red input LED (middle). This situation isn't always defective. The output voltage or current of the module is indicated by the red FAULT LED.

Applications:

For all SD (super series EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system.

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Circuit Module PSM 310

OEM PART NO. 40042254

Description:

In EMD locomotives, the term “CIRCUIT MODULE-PSM 310” designates a Power System Manager module variation intended exclusively for the EMD SD70 series locomotive models. The EMD Locomotive is a line of powerful diesel-electric locomotives that were first produced by EMD. The PSM 310 variation is tailored to the unique electrical configurations and powertrain architecture of the EMD locomotives. In the EMD power configuration, it would incorporate extra sensors for traction motors, alternators, and power converters. More accurate torque control tuning and low-load efficiency improvement are made possible by updated firmware for the EMD electrical systems.

Specifications:

- The PSM310 disperses the power to the computer chassis by stepping down the PRG300's 74 VDC input to +/- 12 VDC. For the PSM310 to operate as intended, the PRG300 must supply a minimum of 60 volts of input.

- The top green LEDs show that the supply is operating within the designated 5% of its rated output voltage. This indicates a voltage of 11.4 VDC to 12.6 VDC at the load. The 12 VDC output side will have negative values for these.

- A transient in the input line that is greater than the input range of 55–90 VDC is indicated by the red input LED (bottom middle). This situation isn't always defective. If this LED remains lit, there may be a problem with the PRG300's 74 VDC supply or the PRG300 itself may be broken. The module has + & - 74 VDC input test points. Additionally, the PSM310 has +12 VDC, -12 VDC.

Applications:

For all SD (super series EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system.

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Circuit Module PSM 320

OEM PART NO. 40042256

Description:

A model-specific power systems management circuit board called the CIRCUIT MODULE-PSM 320 is designed to perform control, optimization, and monitoring tasks in accordance with the precise requirements of EMD’s SD80 diesel locomotives. The SD series diesel-electric locomotives from EMD are intended to be integrated with the 320 version. Due to differences in engine layout between the SD80 and SD70 versions, compatible electrical systems are needed. It would include special sensor integration and I/O interfaces for tractive motors and SD80 alternators. firmware updates with presets and algorithms designed to enhance or control SD80 power management gives the SD the ability to precisely control several engine and generator power units. For the SD electrical architecture, fault protection, load balancing, control, and monitoring.

Specifications:

- The Power Distribution Panels (PDPs) receive power from the PSM320, which reduces the 74 VDC input from the PRG300 to +/- 15 VDC. For the PSM to operate as intended, it needs to receive at least 60 volts from the PRG300. On the faceplate of the PSM320, there are three LEDs. 1 and 2. The green LEDs at the top show that the supply is operating within 5% of its rated output voltage. This indicates a voltage of 14.25 VDC to 15.75 VDC at a load. These figures will be negative when the output voltage is -15 VDC. 3. A transient in the input line that exceeds the input range of 55–90 VDC is indicated by the red input LED (middle). This situation isn't always defective. If this LED remains lit, there may be a problem with the PRG300's 74 VDC supply or the PRG300 itself may be broken. 4. When the output voltage or current of the module is not within tolerance, the red FAULT LED illuminates. There are +/- 74 VDC input test pins on the modules. The PSM300 also features +5 VDC and a common.

Applications:

EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system..

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Circuit Module FCF 301

OEM PART NO. 40058133

Description:

The FCF is in charge of giving the CPU feedback from the Companion Alternator. The data comprises the output of the CA for each phase as well as the total of the three stages. The circuitry for zero cross-detection is included in this module. The timing of each companion alternator phase’s sine wave’s transition from the negative to the positive half-cycle is determined by this circuitry. The FCF notifies the CPU module in the computer chassis that a phase has crossed zero when the zero line is crossed. The CPU calculates how long it will take to generate a weak gate pulse at the right phase angle for a given load request based on this signal.

Specifications:

- CA1, CA2, and CA3 (relative measurements) These are the phase-to-phase voltages that the CA is supplying. Genes A, B, and C (measurement related to 15V COM) The FCF produced these five VDC square wave pulses, which were then transmitted to the CPU.

- Each time the corresponding phase passes through zero. CAV (measurement related to 15V COM): This is the composite that represents the real CA output that is delivered to the ADA. The measured scaling factor is 31 VAC output/VDC. 15V COM measurement range: +15V to -15V. The zero-cross detection circuitry of the module uses this as its reference voltage.

Applications:

For all SD (super series EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system..

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Circuit Module FCD 300

OEM PART NO. 40042250

Description:

The circuitry for the gate amplifier required to amplify the weak gate signals transmitted from the CPU module to the FCD is contained in this module. The SCR assembly is then received with the boosted gate signals. The three-phase AC output of the aux generator provides power to the gate amplifier circuit.

Specifications:

- Contact us for detailed Specification

Applications:

For all SD (super series EMD diesel Electric Locomotive replacement , the Locomotive holds with EM-2000 control system

Note:

This module is direct replacement solution without any additional modification on the locomotives.

Coupling Assembly Accessory Drive

OEM PART NO. 8323180

Description:

The parts of a diesel locomotive that link and transfer power from the engine to the several accessory systems are referred to as the coupling assembly for the accessory drive. It transfers rotational power from the crankshaft of the engine to operate fans, pumps, generators, compressors, and other accessories. Through a rotating power take-off interface, the accessory drive coupling is a crucial subassembly that allows the diesel engine to dependable power auxiliary systems.

Specifications:

- EMS-12, SAE-J431, ET-827, AI-2400, ASTM-2000,

Applications:

All EMD Engine Models 567, 645, & 710.

Traction Motor Bearing Cover Assembly Drive End

OEM PART NO. 40105347

Description:

The protective casing and parts encircling the bearings on the drive end of electric traction motors used in locomotives and other electric vehicles are referred to as the traction motor bearing cover assembly on the drive end. The lubricating components, shaft seal, and drive end bearings are enclosed and shielded by a cast metal bearing cover.

Specifications:

- Raw Material Spec.: Warm hardened high strength aluminum alloy-AISI7Mg WA (DIN 1725) material no: 3.2371.61 (A356)

- Hardness: 75-110 ON Test Bar and 75 Minimum on Casting

- Casting Process: Steel Gravity Die Casting

- Radiography Test: Will be conducted for qty 1: 10 rations as per applied standard to aluminum casting

Applications:

AC Traction Motor Model 1TB2630, 1TB2830, 1TB2830B, A2916-8, AND A2916-8LW.

Labyrinth Sealing Ring

OEM PART NO. 40063837

Description:

Labyrinth is a type of mechanical seal which will be mounted in A/C motors that provides a tortuous path to obviate leakage. Labyrinth seal on rotating shaft provides non-contact sealing action by controlling the passage of fluid through a variety of chambers by centrifugal kineticist.

Specifications:

- Raw Material Spec.: Warm hardened high strength aluminum alloy-AISI7Mg WA (DIN 1725) material no: 3.2371.61 (A356)

- Hardness: 75-110 ON Test Bar and 75 Minimum on Casting

- Casting Process: Steel Gravity Die Casting.

- Radiography Test: Will be conducted for qty 1: 10 rations as per applied standard to aluminum casting.

Applications:

AC Traction Motor Model 1TB2630, 1TB2830, 1TB2830B, A2916-8, AND A2916-8LW.

Digital Speed Indicator (Speedometer)

OEM PART NO. 40153775

Specifications:

- Operating Voltage1: 0-20VDC

- Display: 3Digit 0.8”red seven segment

- Frequency Range: 0.2Hz-6KHz

Applications:

For all EMD ,Alco and GE locomotives.

TRANSFORMER T2

OEM PART NO. 8234831

Specifications:

- Primary volts: 460/230 at 60Hz terminal H1 H2 H3 H4.

- Secondary volts: 115 tolerance+/-2%

- Max primary Open circuit: Exciting current shall not exceed 0.46AMP (RMS) @230VAC(RMS) 60 Hz.

Applications:

All kinds of Diesel Locomotives main Generators TA10 to TA17.

TRANSDUCTOR

EMD PART NO. 8351993/ 8331100

Diesel Electric Locomotive Aftermarket Parts- GE

IGBT Positive(PM+) & IGBT Negative (PM-)

17FM774A1 & 17FM775A1

Description:

Converts a fixed DC voltage into an AC voltage with variable frequency and amplitude. This AC voltage is then utilized to govern the speed and torque of the motor.

These goods, which come in various ratings, are what we manufacture for locomotive applications. This product has been validated by numerous railway manufacturers worldwide and is certified in accordance with IEC requirements.

IGBT Control Panel

Panel Rectifier IGBT

Vertical Bus Bar

41A296332BLP12 / 41A296332BLP2 GE1412

RELAY CPR & GFR

17LV66J46VG7043

FCFP: FORCED COMMUTATION FLASHOVER PANEL- 17FM608D2

Description:

A Forced Commutation Flashover Panel In diesel-electric locomotives is a component designed to address issues related to electrical flashovers and commutation failures in the locomotive’s traction motor and power control systems.

Diagnostic Info Display (DID)

PC2796 PB9785 / 58B-06-00111

Arc Chute

GE0696 GE1072 / BF2134

Cards

17FE101B1

Cards

17FE110B3R

Cards

17FE119A3

Capacitor Bus Bar

41A296332BLP13 GE1413

Capacitor, Filter

41A296302CDP6 /

GE1296/XA4876

Resistor Panel

XA4327 GE0182

Resistor Panel (R1)

GE0152

CIO Backplane for 17FL440

GE0152

VAM Panel 8 channel

84A218010P1 VAM XA3720

VAM

84A218010P1 VAM XA3720

17FM681A1 GE0857

Bus Bar

41A296332BLP13 GE1413 / 41A296332ALP10 /

CONT. INT. ASM

41C66278165

Electric Locomotive Parts

DRIVER DISPLAY UNIT (DDU)

EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/0487/C

Specifications:

- LCD Display Size :10.4 inch

- variation from 77V to 137.7V

- Power supply cable :110VDC,3Pin Miniature Circular Connector.

Applications:

3ϕ Electrical WAG-9,WAP-7,WAP-5,VCU Communication Control Systems. Like, DEMU, MEMU, ACMU, Metro Coaches Etc.

PRIMARY VOLTAGE TRANSFORMER

EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/0009 ALT-C

Specification:

- Maximum Voltage :36KV

- Ratio :25000/200

- Rated Output :30VA

- Maximum Output :150A

- Limiting Current :1.5A

- Creepage Path :≥1190mm

Applications:

WAG-9,WAP-7,WAP-5 & All Over end Electrical Trainsets & Locomotives Etc.

SURGE ARRESTOR

EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/0016 ALT-B

Specifications:

- Rated Voltage :41.4kv

- Impulse Withstands Current :100ka

- Rated Current :10ka

- Maximum Operating Voltage :33kv

- Creepage Distance :972mm

- Weight: 15-16kg

- Flashover distance :475mm± 2mm

Applications:

WAG-9,WAP-7,WAP-5 & All Over end Electrical Trainsets & Locomotives Etc.

FIRE DETECTION UNIT (FDU)

DISPLAY EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/057

Specifications:

- Supply Voltage- 6 to 120VDC

- Power Consumption-250mA± 20%

- Contact rating alarm & fault relays-120VDC/2A

- Weight-7.1kg

- Service life of the Fan-65,000hrs

Applications:

WAG-9,WAP-7,WAP-5 Etc.

HALL EFFECT ACTIVE SPEED SENSOR

EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/0528 ALT-A

Specifications:

- Input Voltage- 15Vdc To 30Vdc

- Output Type-Open collector type 90 degree Phase shift

- Pulse-120 Pulse

Applications:

WAG-9,WAP-7,WAP-5,, 6FRA , DC Traction Motor Etc.

CURRENT TRANSDUCER

CURRENT TRANSDUCER EQUIVALENT TO CLW SPECN. NO. CLW/ES/3/SK- 2/0084

Specifications:

- Nominal Current-1000A RMS

- Turns Ratio-1:5000

- Bandwidth-0 to 100Khz

- Current Consumption-25mA

Applications:

Industrial Applications & All kinds of Electric Locomotives.

DISTRIBUTED POWER WIRELESS CONTROL SYSTEM

EQUIVALENT TO RDSO SPECN. NO. RDSO/2019/EL/SPEC/0142 REV-0

Specifications:

- Controller-ARM Cortex 32bit

- Clock Speed-300MHz

- Ram-512kb,UARTx4,Ethernetx1

- Power Supply-110vdc

Applications:

Diesel Electric Locomotive, WAG-9,WAP-7,WAP-5 & All kinds of MU Locomotives Sets Etc.

LHB Coach Parts

SPEED SENSOR (CURRENT)

EQUIVALENT TO OEM Part.No.1135435/10012 (or) 1135456/20013 (or) STN 31450/205A 18U

Specifications:

- Nominal Voltage (Ub): 15V DC,

- Operating Voltage Range: 12V to 16V DC,

- Voltage Ripple: 200mV Max,

- Signal Interface: Current Signal,

- Output Signal Form: Rectangle,

- Load Resistance: 100 Ohms,

- Air Gap (Sensor to Phonic Wheel): 0.9 ± 0.5mm,

- Frequency Range: 1Hz to 8 KHz,

- Insulation resistance: >500Mohms @ 500V DC.

Applications:

For all LHB Axle Motor Disc type.

SPEED SENSOR (VOLTAGE)

EQUIVALENT TO OEM Part. No.1/604501/2000 (or) 790040267

Specifications:

- Nominal Voltage (Ub): 15V DC,

- Operating Voltage Range: 8V to 15V DC

- Voltage Ripple: 200mV Max,

- Signal Interface: Voltage Signal

- Output Signal Form: Rectangle,

- Load Resistance: 100 Ohms,

- Air Gap (Sensor to Phonic Wheel): 0.9 ± 0.5mm,

- Frequency Range: 1Hz to 8 KHz,

- Insulation resistance: >500Mohms @ 500V DC.

Applications:

For all LHB Axle Motor Disc type.

N1 BOARD

EQUIVALENT TO OEM Part. No.: 1/600009 (OR) 1/600009A

Specifications:

- Input Voltage: 24VDC

- Current: 4.2Amp

Applications:

WSP System for LHB Coaches.

N2 BOARD

EQUIVALENT TO OEM Part No.: 1/600008 (OR) 1/600008A

Specifications:

- The current ratings of the voltages 5 VDC-1.6 Amp,

- 15VDC-500ma

Applications:

WSP System for LHB Coaches.

MV BOARD

EQUIVALENT TO OEM Part No. 1/600006 OR 1/60000 OR 1/600006A

Applications:

WSP System for LHB Coaches

PHONIC WHEEL

OEM PART NO: 1.2.748/ 1/604545

Specifications:

- Number of Teeth: 80

- Pressure Angle: 20°

- Air Gap between Sensor & Phonic Wheel: 1.0 ± 0.1mm

- Material: Ferro Magnetic

Applications:

For all LHB Coaches & Train sets fitted with independent disc braking system.

Dump Valve

GE Board

Modified Junction Box

Mining Truck Parts

IGBT Positive(PM+) & IGBT Negative (PM-)

17FM796A1 /A2/A3 GE1255,

17FM797A1 /A2/A3 GE1256

Description:

Converts a fixed DC voltage into an AC voltage with variable frequency and amplitude. This AC voltage is then utilized to govern the speed and torque of the motor.

These goods, which come in various ratings, are what we manufacture for locomotive applications. This product has been validated by numerous railway manufacturers worldwide and is certified in accordance with IEC requirements.

Speed Sensor

XA2874, XA4256

Speed Sensor

GE1155

Speed Sensor

VJ0972 PB0101 VS7923

Speed Sensor

GE0139

Converter, Gate Driver

41A296352CYP2 GE1257

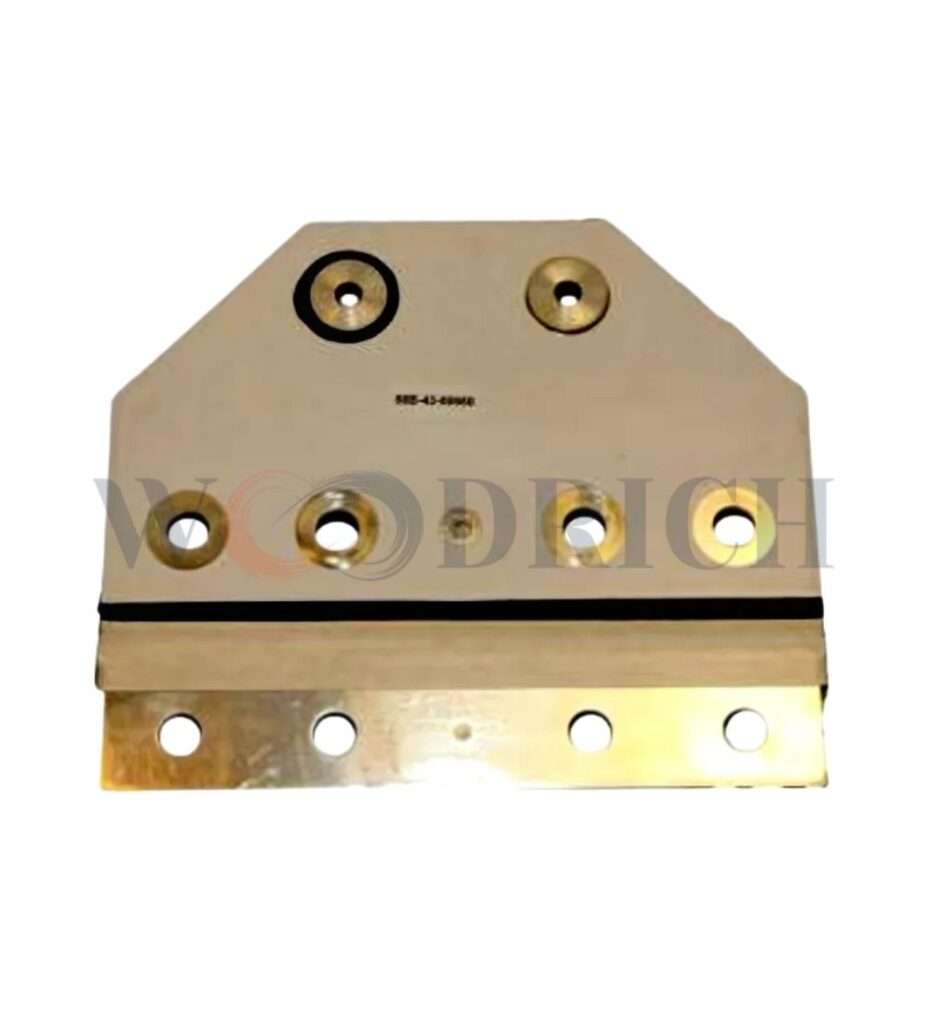

Power Supply

17FH41A1 GE0755 / 17FH43A3 / 58E-43-00061

Diode Assembly

Card 17FB173

GE1209

Card 17FB160

GE0368

Module

VS7373

Kit Contactor

GE1836 / VE1183

Board Printed Wire

41C666570G1 GE0177

Sensor AC - DC

41A296328AKP7 GE0170

Panel, ICP

17FL386A1 GE1302

Multi-Function Switch Assembly

PC1709

Card 100

AK1991

Card 140

AK7945

Card 104

GE0309

Card 17FB160

GE0368

Card 17FB176

GE1209

Card 17FB179

GE1502

Card 17FB187

58E-43-10260

Module Assembly

GE1486/ 58E-43-00400,

GE1487/ 58E-43-00410

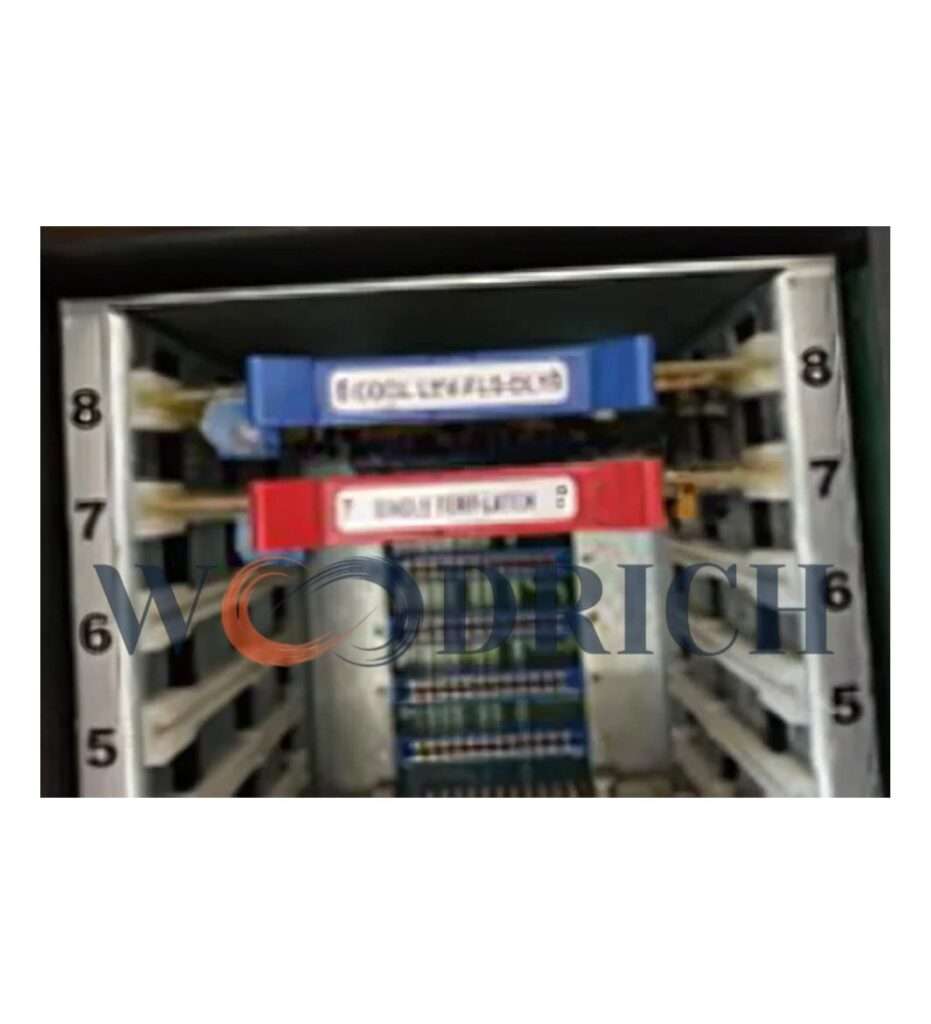

Card, Flsher/ Coolant Level

VJ8805

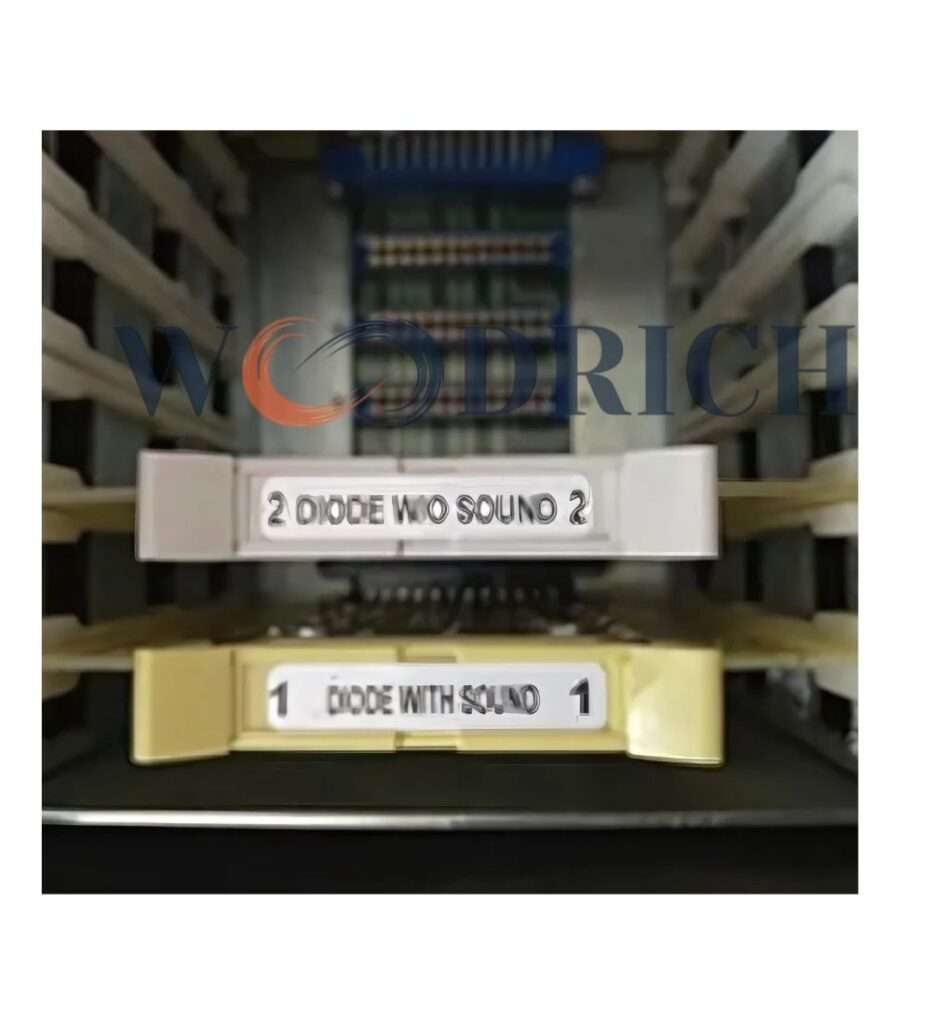

Card, Diode (W/Sound)

VJ9023

Card, Diode (W/O Sound)

VJ9024

Card, Single Temperature

PB5672

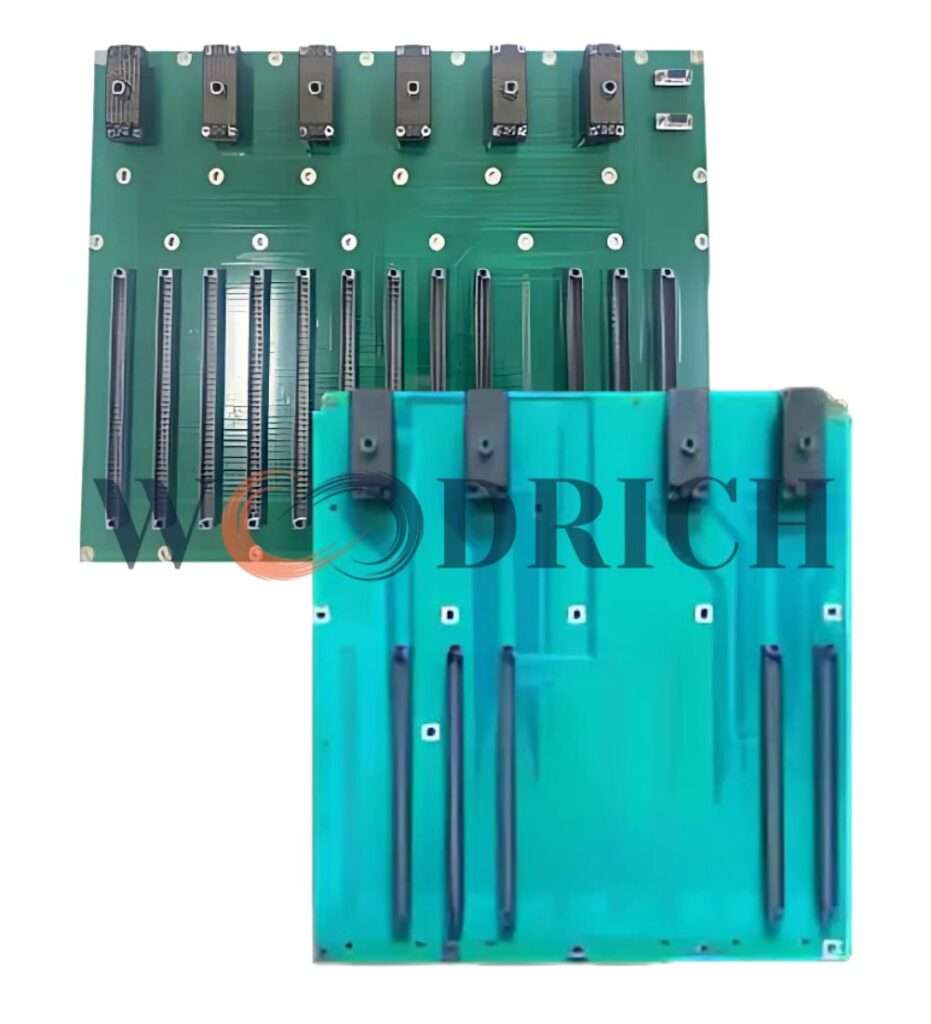

Back Plane

GE1483 41A325938G2 / VE8195